The problems encountered during the extrusion of PVC foam sheets can be basically classified into four categories,

First, stability

Second, the melt strength

Third, lubrication

Fourth, decentralization

These four types of problems, especially the first three types of problems, will restrict each other and cross affect each other. Sometimes it is difficult to distinguish them immediately from the superficial phenomenon. It is necessary to observe and analyze the problem and find the root cause to fundamentally solve it.

Inadequate stability will affect the whole board surface. The board surface will turn yellow and the foam sheet will be brittle.

Insufficient melt strength will lead to large foam cell and long longitudinal foam.

To judge whether the melt strength is insufficient, the direct method is to press the sheet wrapped on the middle roll with your finger behind the three rolls. When the melt strength is good, you can feel the elasticity. If it is difficult to spring up after pressing, the melt strength is poor. It is difficult to judge whether the temperature is reasonable because the screw structure and cooling mode are quite different.

Generally speaking, the temperature in Zone 3-5 should be lower within the allowable load of the extruder.

In order to obtain uniform foamed products in foamed pipes, it is also necessary to ensure that PVC materials have good melt strength. The foaming agent developed by the company is developed to solve this problem of foaming products, which can effectively improve the quality of foaming pipes.

Lubricants are divided into external lubricant and internal lubricant. The external sliding is beneficial to demoulding and the smoothness of the plate surface. The external sliding is too little, and the temperature in zone 5 of the extruder is difficult to control and easy to rise, which will lead to high temperature of the confluence core, blisters, yellowing and other problems in the middle of the plate, and the plate surface is not smooth; The precipitation will become serious due to more external sliding, which is shown in the structure in the mold and the precipitation on the plate surface due to external sliding, and also in the irregular back and forth movement of some individual phenomena on the plate surface. The inner slip is beneficial to plasticization and melt fluidity. The thickness of the plate is difficult to control if the inner slip is insufficient, which shows that the plate is thick in the middle and thin on both sides; The phenomenon of high temperature of the confluence core is easy to occur due to more internal slip. Poor dispersion will lead to unsmooth plate surface.

Process temperature control problems:

The four issues mentioned above are fundamental, fundamental and deep-seated.

Compared with the above four problems, the process temperature control is much more intuitive. It is a surface problem, but poor temperature control will lead to fundamental problems. When the processing temperature is increased, the material stability time will be reduced, resulting in stability problems; The original lubrication balance will be broken.

Generally, the external lubrication is insufficient, especially in the later period, the amount of external lubrication should be increased; The increase of temperature will also lead to the decrease of melt strength, the increase of foam cell, the decrease of foam cell number, and the brittleness and fracture of the sheet; The increase of temperature reduces the melt strength and also reduces the melt viscosity. The reduction of viscosity reduces the shear dispersion ability. For screws with weak dispersion ability, uneven dispersion sometimes occurs.

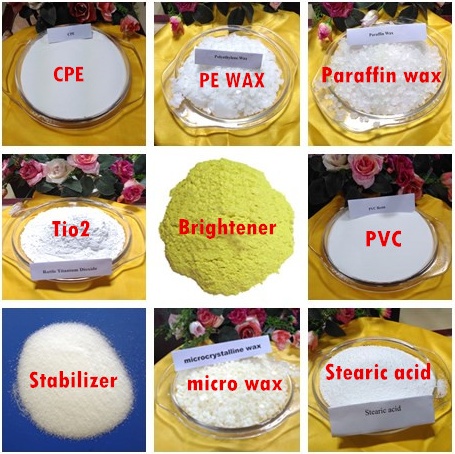

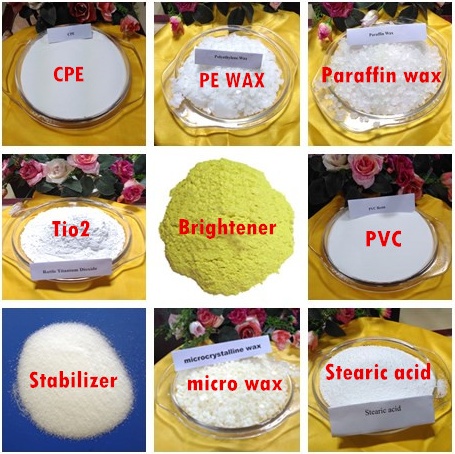

We have done chemical products for over 30years. Our main products include PVC Resin, CPE, TIO2,Pe Wax, Paraffin Wax, Stabilizer ETC.